Updated April 29, 2016

We will be posting progress reports here as we do upgrades and maintenance on our cars during the off season. With four cars in our stable, it will require the cooperation of the entire team to get what needs to be accomplished completed. – Roger

‘71 Chevelle Wagon:

September 28, 2015: Modified roller lifters to provide improved oiling to the top of the 406. This will improve the life of the pushrods, rockers, lash caps and valve springs. Chris tested the valve springs and they are good to go for 2016. [Improving the oiling to the upper end of the engine has helped, we have 13-hits on the engine and have NOT had to adjust one valve thus far]

October 6, 2015: We’re also going to make an intake manifold change from our Motown manifold to the Edelbrock Super Victor and see it that improves the power: [We have not seen any performance increase with the Super Victor thus far, but the car has been very consistent with the new manifold early in 2016]

October 11, 2015:

We fired the motor with the new Super Victor intake on the car today which Chris matched-ported, and we picked up 200+ RPM of stall over the old manifold so it’s looking promising! With the lifter modifications we also have plenty of oil on the top end of the motor. Front Strange shocks are on the way for installation. – Roger

October 16, 2015:

Today Chris got the new Strange double-adjustable shocks installed in the front of the car. Now to get the rear shocks back to Aldan for rebuilding and the Chevelle will be ready to go for 2016! – Roger

December 5, 2015:

Today Chris pulled the rear shocks off the Chevelle to send them back to Aldan for rebuilding. The right shock is dead. – Roger

January 28, 2016:

Today the rebuilt Aldan coil-over shocks are back on the Chevelle!

February 6, 2016:

Today we installed the valvetrain on the Chevelle and fired it off:

‘85 Mustang:

October 17, 2015:

- Installed 105-amp alternator and checked charging.

- Reworked rear upper control arms to correct bind in rear suspension.

- Ground lip of R/F lower a-arm to free brake rotor when tire is off the ground.

- Opened hood cowling to reduce under hood temps.

- Repair positive battery lug in rear bumper which had an intermittent short to ground.

- Adjust steering column position to provide increased clearance between steering shaft knuckle and header pipe.

October 24, 2015:

Today we installed the 3″ studs in the front brake rotors and a taller air cleaner element. We worked on the brakes but are still not satisfied with the brake pressure at the rear calipers. Guys, when you install rear disc brakes on a disc/drum car it can create problems, it can be difficult to get enough fluid volume from a factory disc/drum master cylinder to move the larger pistons on a disc brake system! We believe we’ve found a solution, a Wilwood big-bore 1:1 dual master cylinder designed for 4-wheel disc brakes. We’ll know more in about a week! – Roger

November 1, 2015:

Today we installed the big-bore Wilwood master cylinder, but with that bore we could not get the required line pressure necessary for good brakes.

November 27, 2015:

This past week we purchased a brake pressure gauge to isolate the problem. We had over 800 psi at the master cylinder but zero pressure at the rear calipers. Chris disconnected the brake line at the master cylinder and back at the rear axle and blew out the line, bled the rear brakes again and we now have the rear calipers working! Clearly there was some obstruction in the brake line running the length of the car. – Roger [Paul reports the brakes are greatly improved in early 2016]

Factory front wheel studs

November 28, 2015:

Today Chris installed all new heavy-duty toggle switches in the dash to replace the troublesome switches that came with the car. This should end that problem and should complete the scheduled updates for the Mustang for 2016! In February 2016 we weighed the Mustang, 3300# with driver & fuel – Roger

‘57 Chev:

1) Build new headers, have them coated and match-port header plates

2) Replace factory single master cylinder with tandem cylinder

3) Replace rear coil-over springs, reset preload

December 14, 2015:

Today we got the ’57 moved so Chris can begin modifying the 1-7/8″ Hedman fenderwell headers we purchased for an S-10 to fit the old ’57. This is going to require a LOT of patience and skill to move the tubes for proper clearance and tuning length. Unfortunately no one today makes a large-tube fenderwell header for the tri-5’s these days and would need to be custom made. So Chris has decided to handle this difficult project.

I’ve also ordered new coil-over springs for the rear of the car as the left spring has sagged and taken a set. After replacing the springs we’ll need to reset the chassis preload and wheelie bars. – Roger

December 19, 2015:

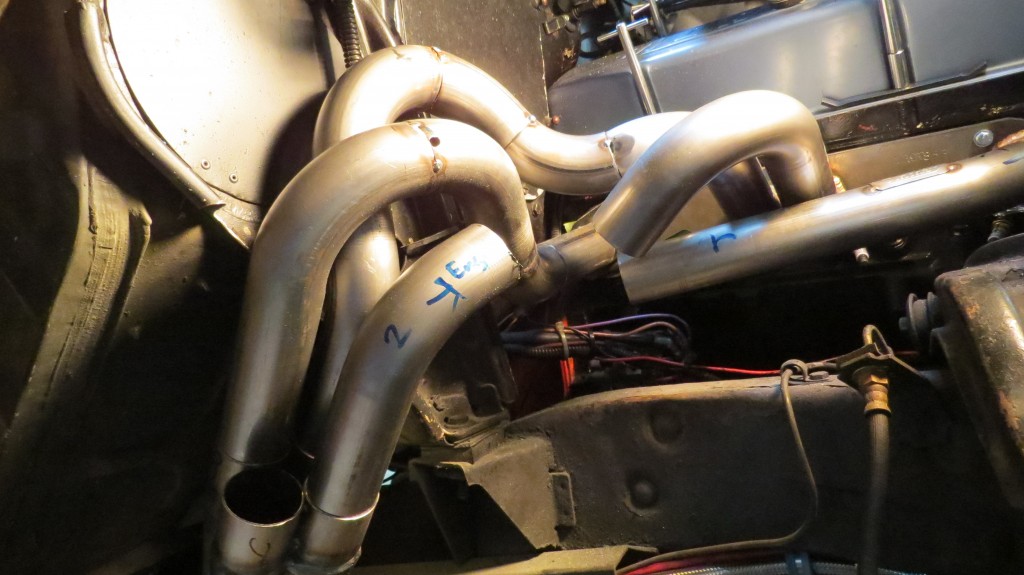

Today, Chris started cutting & fitting pipe for the new 1-7/8″ fenderwell headers on the ’57:

Tacked welded right header. Chris moved the tubes back to give us more header to tire clearance. All tube lengths are within 1/4″

December 26, 2015:

Today Chris got the left side header tack welded together and ready for final TIG welding, and Paul and I got the new rear coil-over springs installed in the car. Next we’ll be installing the new tandem master cylinder in the ol’ buggy! – Roger

December 29, 2015:

Driver’s side header is nearly completed, new master cylinder and brakes lines installed ready to bleed the brakes. Chris is doing a GREAT job! – Roger

New tandem master cylinder from Eckler’s. Features same 1″ bore as factory cylinder, identical pushrod depth.

January 1, 2016:

Today Chris and I got the brakes bled after replacing an old line, and adjusted the master cylinder pushrod length and the brakes are ready to go! Thanks son!

January 11, 2016:

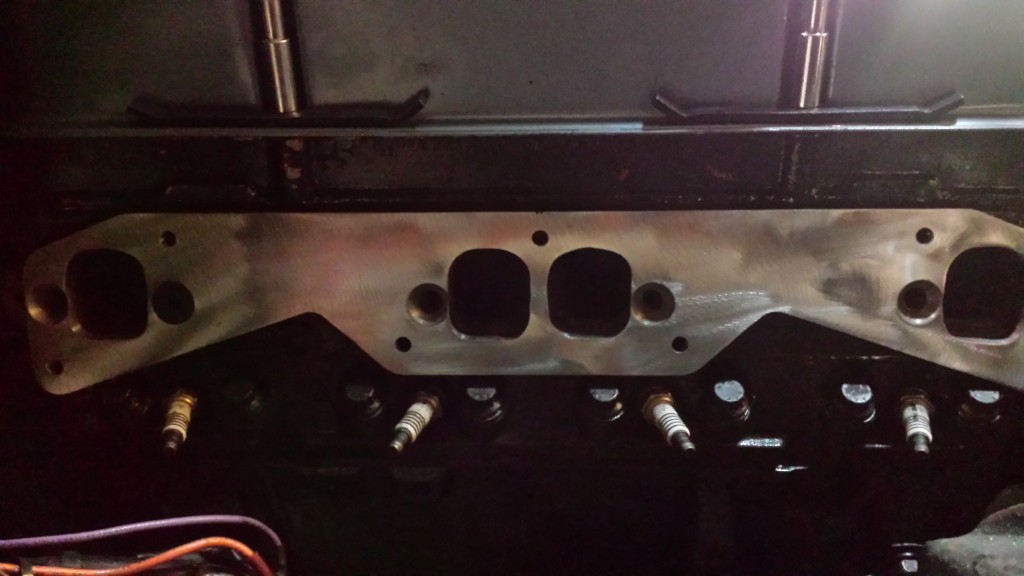

Today Chris finished the headers and they are looking GOOD! Now out to be coated while Chris works on the header plates.

During this winter we are conducting detailed component testing on our cars. Please see our new page devoted to Electronic Diagnostics.

January 16, 2016:

Today Chris got the header plates done for the headers, and cleaned up the wiring going to the starter by mounting a power lug on the firewall. And Paul got the new headers out to be coated.

January 23, 2016:

Today we got the valve train setup on the ’57 waiting for the headers to return from Performance Coatings in Auburn, WA. We also had the time to clean up the shop! – Roger

January 30, 2016:

Today we got the new headers on the car and fired it off. Plus we weighed the car thanks to Barry Hobson who loaned us his scales, 3633 lbs with driver. A video/slideshow of the finished project. A great job by Chris who fabricated the new pipes!

All that’s remaining to get it out to the strip is recheck the valve lash, change the oil & filter, & clean the old buggy! See you at the strip! – Roger

Like last winter when we built two motors, this has been another very busy off season! We have made excellent progress on Paul’s Mustang which is a work in progress, and the ’57 header work by Chris was a major accomplishment which only he on our team had the expertise to make it happen!

We’re looking forward to hitting the strip in 2016!- Roger

==========================

‘66 Tempest:

March 7, 2016:

Today Chris and I got my old refurbished 830 Holley installed on Torri’s ’66 Pontiac Tempest, and adjusted for the strip. Still can’t believe how much pump shot her car has to have at the hit which requires 50cc accelerator pumps on both ends and .045 nozzles! We’ll see if the 830 picks her car up over the reliable 750. I’ve always had good luck with the 830.

The last time the 830 went down the strip was in 2003 on the Chevelle, and over the years it was cannibalized for parts for our other carburetors. This winter I put it back together to run again!

We also scoped her ignition system and charging system, all looks in good shape! – Roger