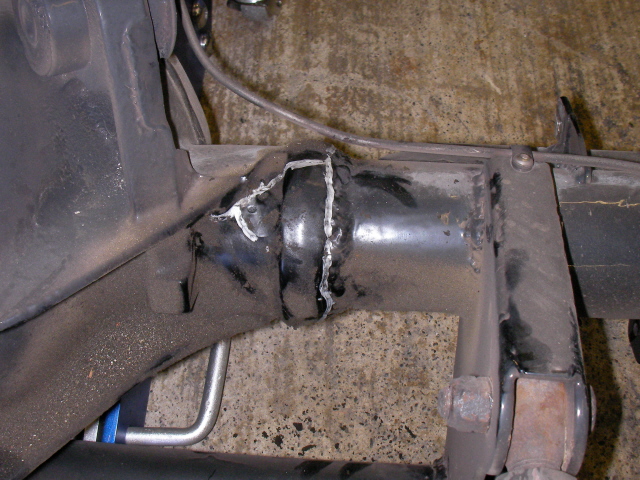

10 Sept 2011: Today Chris removed the bent and cracked 12-bolt from his Chevelle. Below are a couple of pictures. The old 12-bolt with Summers spool, axles, c-clip eliminator kit and caps gave us many years of excellent service. It just gave up after many years of abuse. The cracks are highlighted below:

We’ll be replacing the complete rear end with a housing fabricated by Bill Scribner, new ladder bars and track locator, Strange center section (extra unit from our ’57) with new large-pinion 4.71 Pro gears, Strange spool and Moser axles. More as the project moves forward!

15 September 2011: The old 12-bolt housing is now in the hands of Bill Scribner. In the interim, Chris and I will be setting up the new 4.71 gears in the Strange center. – Roger

24 September 2011: Chris, Paul and I put together the Strange center section with the new 4.71 big-pinion gears today. All went very well!

Below is a video provided by HotRod showing the assembly of a Strange Dana 60 ring & pinion. The basics apply to installing all gear sets:

Update 10 December 2011:

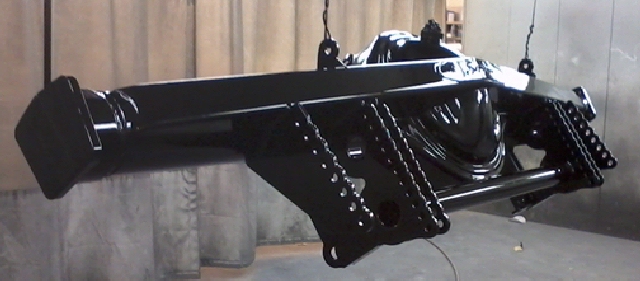

Scribner’s making progress on the new housing:

6 Jan 2012 Update:

The new Scribner Pro Housing is nearing completion:

12 January 2012: Today Chris got the housing painted

12 January 2012: Today Chris got the housing painted

15 January 2012: Today we got the new 9″ under the Chevelle, set the ride height and pinion angle

25 January 2012:

28 January 2012:

Today Chris got the wheelie bars installed, we adjusted and bled the rear brakes and installed the wheels and new slicks. Except for installing the new heim joints in the track locator, the project is completed!

On March 25th 2012, the Chevelle hit the track with the new rear end: Test & Tune, March 25th 2012, Pacific Raceways

I was a bit surprised when we removed the 6.00 gears after only 3-passes and saw the wear pattern on the outer edge of the ring gear. We didn’t set up those gears and it was obvious they were not set up deep enough. This was confirmed when the pinion depth of the new 4.71 gears were the same exact depth dimension (very unusual) as the 6.00 gears and when we checked it with marking compound, it was clear we needed to move the pinion deeper to get the proper contact pattern!

I cannot stress enough the importance of deburring all the teeth on the new gears and making sure there are no burrs on the backside of the ring gear prior to installation.

It was also interesting to see that the Strange Dana 60 case has internal adjusters for setting the backlash and preloading the carrier bearings. Sure beats the old spreader which was needed to literally spread the case to install the carrier and shims!

GOOD VIDEO!

Roger, I have always used 12 bolts and messed with Dana 60’s

Either of you have some feed back on the 9″ Ford? Are they easier to maintain and do they have more gear ratios available?

Yes, the 9-inch Ford is easier to set up the gears, pinion depth and more ratios are available between the large and small pinions.

Plus the housing will be back-braced which greatly decreases tube deflection and eliminates the required c-clip eliminator kits required on the 12-bolt.

Looking good! 🙂 Scribner always does really nice work as he is very meticulous!

Yes he is!

IT HAS BEEN AT BILL’S FOR A WHILE, BUT WE SHOULD BE GETTING IT SOON SO WE CAN FIT AND FINISH THE JOB. WILL BE VERY NICE WHEN IT IS ALL DONE AND SPECIAL THANKS TO DAD FOR GIVING UP HIS EXTRA THIRD MEMBER! IT SAVED ME ALOT OF MONEY!

Went over to Scribner’s Friday the 22nd he just got the brackets from the water cutter and said we should have the rearend in a couple of weeks.

That’s good news!!

Bill Scibner called Chris last night and stated the housing is done and he had ordered the axles. We’re getting close!

I went out today with Chris to pick up the new Ford housing for the Chevelle. The workmanship and details that Bill Scribner incorporated in the housing and brackets is absolutely incredible! He thinks of every detail including the clips for holding the brake lines on the axles tubes. It has been an expensive venture but I believe well worth the bucks! Bill truly takes great pride in his work!

Yes he does! Thanks for coming today.

I enjoyed it and I’m looking forward to getting the new rear in the Chevelle!

Chris, Paul and I got the new 9″ installed in the Chevelle today. I knew Bill Scribner was an exceptional welder, but he duplicated the new ladder bar geometry from the old housing with such precision we didn’t even need to adjust the pinion angle!!

And the ladder bar preload was exactly at zero! With the driver in the car, we gave the driver’s side one flat of preload which should be a good starting point. It truly couldn’t have gone together any better!

The new ladder bars are made locally here by Art Morrison.

Thanks for the help dad! things are coming together really well!

My pleasure! You put a lot of thought into the project which is paying off !

The boy’s picked up the upper wheelie bar struts today. Now just waiting on the two rod ends.

Orbital welding is a specialised area of welding where the arc is rotated robotically through 360° (180 degrees in double up welding) around a static workpiece, an workpiece such as a tube, in a continuous step.

Thanks for share this excellent post with us is really interesting, keep up the good work