Updated July 22nd 2018:

This engine combination below set a personal best on April 22, 2018 when it ran a 10.440 @ 128.44 MPH at Pacific Raceways.

However, in July of that same year we cracked the combustion chambers in our old, iron heads in cylinders #1 & #3 and damaged several pistons and a cylinder wall from the water in the motor. Where we go from here is in doubt – Roger

=========================

3/4/2014: Years back we had a 350 in our wagon, but the Ross piston skirts and cylinders were badly scuffed from a lifter failure. So the block & Scat crank have sat in my basement for about five years.

With the advanced age of our 331 in the ’57, we are considering bringing back our 350 for the 2015 season by punching it +.060 and installing new Wiseco pistons. These new pistons feature the .043 ring package with a 3-mm low-tension oil ring, lateral gas ports for the top ring, anti-detonation groove and coated skirts to minimize scuffing.

First we’ll have the block pressure checked for any cracks and if good will order the pistons and rings. Then have the block bored and honed with torque plates to the recommended clearance and rebalanced. With our 62cc heads off our 331 along with the current 50128 cam and tunnel ram system, the engine should produce 710+ horses at 7500-8000 rpm’s & approximately 558 lbs. of torque at 6000 rpm. This is approximately a 53 pounds of torque increase over our old 331 – the 350 will be 14.0:1 compared to 13.0:1 – so a rear gear change will be needed. We’ll start off with our 5.67 set compared to the 5.83’s that are currently in the car.

With a single 4-bbl manifold such as an Edelbrock 4500 Super Victor and a Dominator like Chris has on the Chevelle with our tighter lobe center 50132 Lunati cam, in the future and with a rear gear change, Paul could run the car in Pro Bracket or Super Street with an automatic down the road. This combination would yield approximately 698 horse @ 7500 and 553 lbs. of torque at 5500. – Roger

UPDATE May 9th 2014: I spoke with Dale Green yesterday and the block is sound, so I ordered the Wiseco pistons and .043 rings this morning. Our 350 project is now underway! – Roger

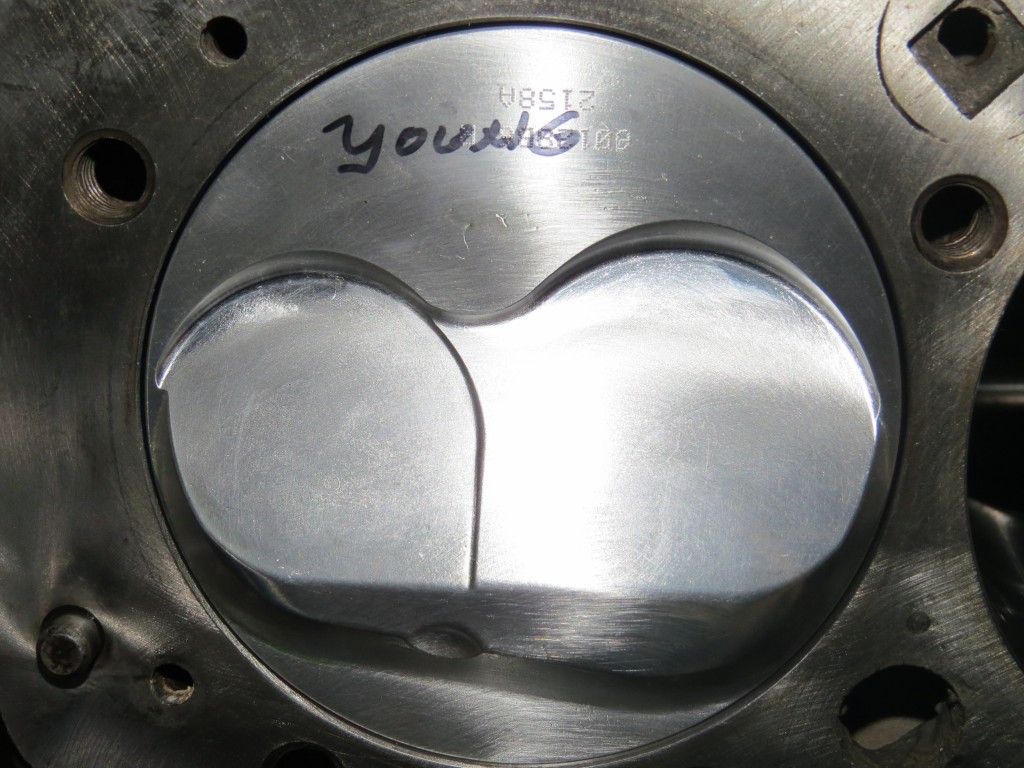

UPDATE May 16th 2014: Our new Wiseco pistons arrived yesterday for our 350. These are completely finished pistons with the domes and valve reliefs deburred of sharp edges. The entire set of pistons is within 1-gram. .043 ring set with 3-mm oil ring, lateral gas ports, anti-detonation groove, coated skirts, the works!

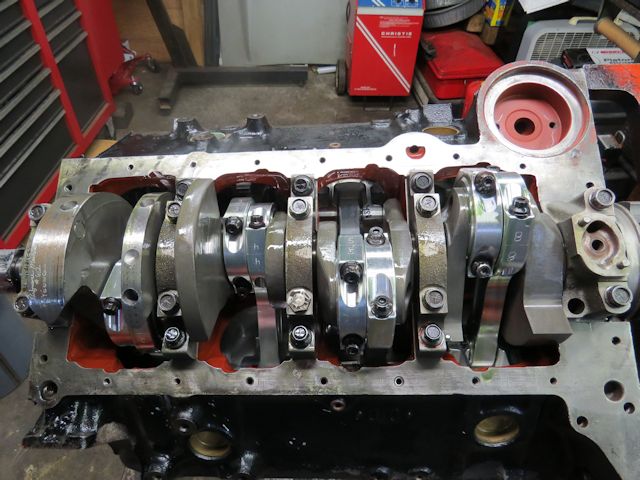

UPDATE June 9th 2014: Today Chris and I picked up the finished block from DG Machine. They did a nice job boring & honing the block, plus they balanced the rotating assembly. They had to use some mallory metal to balance the crank since our bob weight is somewhat higher than with the old Ross pistons. I checked the piston clearance, right on the mark! We’re making progress and on schedule!

Update 9/22/2014: I now have four of the piston-rod assemblies in the block and making progress. File fitting the rings takes the longest to accomplish but is where the power is. – Roger

Update 9/24/2014: All the pistons are now in the block. Next step is to get the 331 out of the ’57, as the heads, cam, belt drive, intake, oil pump and pan are all going on the 350 over the winter for 2015. Plus I need to order the new Stahl fender well headers for the new engine soon!

Update 9/30/2014: Thanks to Chris & Paul, the 331 is out of the car and we now have the camshaft, belt drive and oil pump installed in the 350 from the 331. We’ve installed the cam at 110-degrees lobe center (2-degrees retarded) to take away a tad from the bigger motor on the launch, and we’ve clayed the pistons and have plenty of dome clearance and valve-to-piston clearance with the new Wiseco pistons using our big cam out of the 331. Things are coming together nicely and according to plan!

We’re disappointed to learn that Stahl headers recently closed to give Jerry Stahl a well deserved retirement and we’re working on an alternative. His long-time associate supposedly purchased all the dies and equipment and will be opening shop soon. [Chris later made new headers for the 2016 season].

Update 10/2/2014: The heads are now on the 350 and we leaked tested all the cylinders at this point, all is looking very good! Plus with the smaller domes sparkplug clearance isn’t an issue but we’ll still index the plugs. Prior to installing the heads we checked the Manley 1.625″ valve springs and they are holding up well after 37 runs!

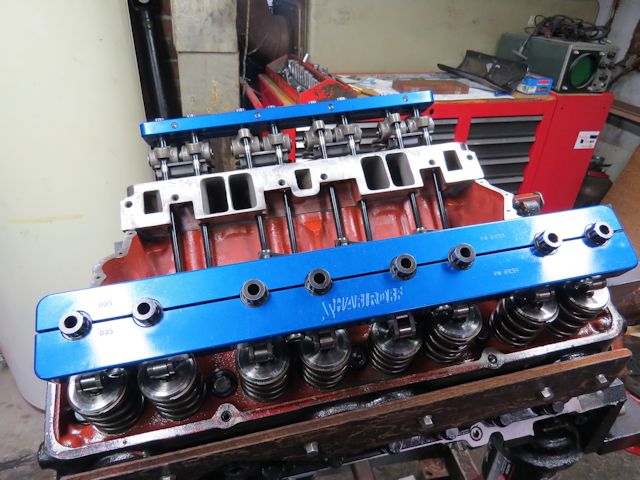

Update 10/3/2014: Last evening we installed the valve train after checking our valve train & rocker geometry because we are dealing with a different block from the 331. As expected our pushrod length was good.

Our next step is to modify the internal scraper in our oil pan to accommodate the longer stroke of the 350 and prime the engine.

Update 10/4/2014: Today Chris modified the internal scraper in the oil pan and adjusted the windage screen position for the longer stroke in the 350. After installing the oil pan we primed the engine to make certain all the Comp fully pressurized lifters and rockers were being lubricated properly.

Update 10/5/2014: Intake manifold is now installed along with the distributor.

All that is remaining is to paint the block and install the harmonic balancer. – Roger

350 Balance Weights & Build Sheet

Checking deck clearance. With the head gasket we run, we’ll have .0515 of quench, right on the mark!!

Valve train installed on 350. 1.625″ Manley valve springs, 3/8″ pushrods, Crower rockers, Shafiroff stud girdle

With the engine out of the ’57, it was time to replace our clutch disc. We get about 45 runs on these Ram discs and about 90 runs on their pressure plate in the ’57: They also make this same disc in a solid hub (no springs) which the car loves but it is absolutely BRUTAL on the transmission and rear gears!

Update October 25th 2014: Today we removed the slicks, axles and center section from our 9″ Ford rear end to change the gear ratio from 5.83’s to 5.67’s for the 350.

Update November 1st 2014: Today we got the 5.67 gears setup in our Strange 9″ carrier for our ’57 with the new 350 in 2015. Took us longer than usual, about four hours to get the pinion depth right, but it’s done. Thanks to Chris and Paul for their help! Now to start getting all this back in the car!

Update January 25th 2015: Today Chris, Paul and I got the new 350 bolted into the car, transmission and driveline installed. Still have a ways to go before firing it off, headers, plenum and carbs, radiator, some wiring but made good progress! My thanks to Chris and Paul for all their hard work! – Roger

Update January 28th 2015: We got a lot done in the past few days, and today we’ll finish by installing the headers to complete the 350 installation. We will be firing the new bullet this weekend to set the ignition timing.

Yesterday I got the intake plenum, fuel lines & carbs installed, installed the valve train, primed the motor once again on the starter motor and all is looking good. We also put some fuel in the fuel cell and primed the fuel system.

Yesterday our new Strange double-adjustable front shocks arrived. It will require some alterations to the lower a-arms (enlarging the shock hole for the adjuster knobs) but we have plenty of time for those alterations prior to the first test & tune in the Spring. [Chris got the shocks installed on January 29th] – Roger

We also got the headers installed so we only need to fill the cooling system and fire the new engine off and set the timing at 40 BTDC. Then send our driver’s belts back to Crow to have them recertified and this old girl is ready to go! – Roger

Update January 31, 2015: Today we fired the new 350 and got the timing set. All looks good! This ends our 350 report, see you at the strip! – Roger

=========================

On another note in April 2014, we installed a new grill in the ’57 and replaced the parking light/turn signal harness up front. Here’s some before and after pictures with the parking lights on:

Night shot:

UPDATE May 7th 2014:

Chris got the new Chevrolet script on the hood this afternoon. Luckily I still have the original 6-cylinder hood as a template to install it properly. Thanks son, good job! This is the identical hood “look” for a ’57 150 with the 235 as our ’57 came from the factory.

The current hood is from a V-8 that I got out of a junk yard many years ago. I didn’t have the heart to cut the factory hood for the hood scoop. Chris wants to pull the glass bumper – the only glass on the car – and repaint it prior to the Wild West Nostalgia Race at Pacific Raceways in July 2014. – Roger

The Wiseco pistons are a little heavier then our old Ross pistons, but the Wiseco pistons use a shorter, 2.250 pin vs the 2.500 pin in our Ross pistons.

I got the Scat crank out of the block yesterday, main bearings and crank look very good. Now to get the block out to DG Machine to have it pressure checked. If ok, then will order the new pistons and rings to get the block bored +.060″ and finished honed with torque plates installed.

This week Chris and I got the block out to DG Machine to have Dale check it for cracks. The project begins!

This past week Chris pulled the bumper, made the necessary repairs and repainted and reinstalled the bumper. Great job son!

Our 350 block checked out sound and Dale Green is now boring and rebalancing the internals for us with the new Wiseco pistons.

I’m pleased with the .0125″ deck clearance we have with the aluminum rods and the new Wiseco pistons. It means if we put steel rods in the engine in the future for Paul to run, we will still have .0025 of deck clearance as 6″ aluminum rods are actually 5.990 in length compared to 6.000 of steel rods.

With the current rod/piston combination and the head gasket we use, we’ll have a quench of .0515 which is right on the mark. Recommended quench is .050 – .060″