After the last race, we heard a “clicking” sound in the motor when cranking that was in rhythm with the valve train. To be safe we decided to pull the old motor and take a look.

Thanks to Chris & Paul, today we got the 331 out of the ’57 and torn completely down. We found a bad lifter bore in the front of the engine that was damaged since the motor was put together 12 runs back. We have three lifter bores that need to be bushed and we’ll get the engine back together to race again in 2013!

My profound thanks to my sons & Pam for all your very hard work today on a HOT day! – Roger

Update: September 26th 2012

Thanks to DG Machine, we have the lifter bores repaired and the engine back together! We removed the restrictors to the lifter galleys and increased the oil pressure slightly. Hopefully the problem is resolved.

We are also replacing our old Moroso stud girdle with the stronger Shafiroff double-bar stud girdle that we have been using on the 406. – Roger

Rolling ‘EZ’ with ISKY Cams – Drag Racing Online – Posted September 27, 2012

Update: October 21, 2012

Chris, Pam and I got the engine back in the ’57 on Saturday. Chris also got the transmission and driveline back in the car. On Sunday Chris repaired the cracked 3-4 shifter rod and we got the shifter installed and adjusted. Don’t ask me how you fracture a 7/16″ heat-treated shifter rod but it was.

Earlier in the week I reinstalled our MSD Timing Control which will give us more flexibility for the starting line conditions we face. We can also advance the timing in high humidity conditions to help compensate for the loss in horsepower.

Now we’re basically down to installing the carbs, headers, radiator and the engine will be ready to fire. – Roger

Update: October 25, 2012

We now have the headers, and radiator installed. I had to replace the primary fuel bowl in the front carburetor due to the threads pulling on the banjo fitting which is not uncommon. Just add some fuel, coolant & connect the battery and it is ready to fire and set the timing!

New 660 primary fuel bowl with old float, baffle, needle & seat, bounce spring & accelerator pump installed.

Update – October 27, 2012:

Today we fired the ’57 and set the ignition timing. All systems look good! We’ll pull the rockers off while it sits during the winter. New shoulder harness in the early Spring and we should be good for 2013!

You are very welcome Dad, just glad it wasn’t something worse so that is the silver lining. 🙂

We were smart tearing it down. Things could have gotten very ugly in a hurry! Back to the Lunati lifters!!

Chris spoke with Dale Green of DG Machine and they will be bushing the two damaged lifter bores and installing new cam bearings in the old block for us.

Looks like we can start getting the motor back together by September!

August 20th 2012:

This afternoon Barry Hobson & Chris picked up the block and took it out to DG Machine to have the three lifter bores bushed, remove the restrictors to the lifter gallies, and install new cam bearings.

We’ll reduce the valve spring pressure back down slightly to previous pressures, up the oil pressure slightly in the motor and will be switching motor oil.

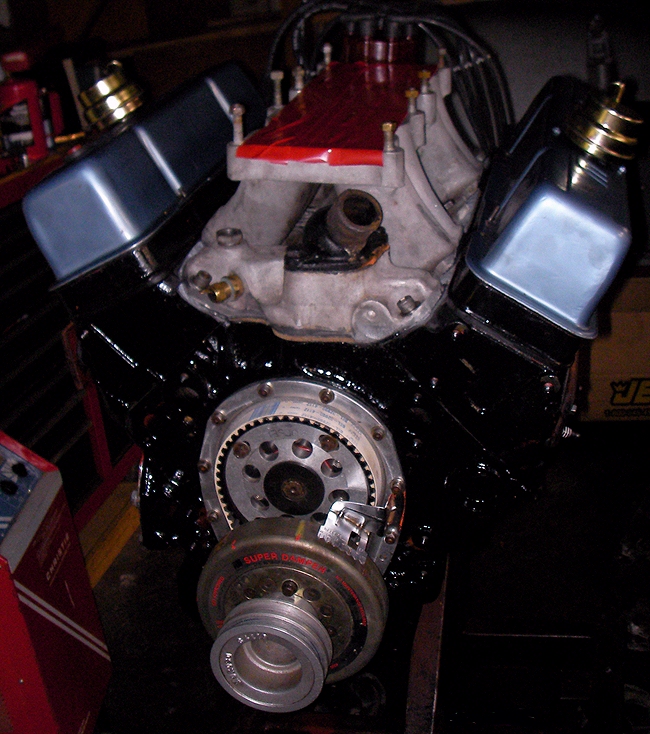

We got the block back from DG Machine with three lifter bores bushed, lifter oil galley restrictors removed and new cam bearings installed.

Today Chris and I got the short block back together. We are also switching to Brad Penn 20W-50 racing oil which Dale Green has been running in his motors with great success. It is a true racing oil with high levels of zinc & phosphorous. (Zinc 1,540 ppm, phos 1,319 ppm).

Engine is back together except for installing the intake manifold. Primed engine today and we have plenty of oil around the lifters and up to the rocker arms. Looking good!

Engine is completely together and Chris painted it this afternoon. And we ordered the same stud girdle we run on our 406 from Shafiroff Racing Engines to replace our old, Moroso single-bar unit.

Installed the new posi-lock (positive retention) breathers on the valve covers today. Should eliminate replacing the o-rings constantly that get cut on the sheetmetal and provide a better seal for the vacupan.

Next, replace my restraint harness and she’s ready to go!

I can’t wait until the ol ’57 makes another pass down the strip, especially at the July Nostalgia race at Pacific as it will be good times.

Paul, I know we were all a bit mystified when we suddenly had lifter bore problems after running the same reliable engine combination for many years. I suspect it was due to two things; 1) The increased valve spring pressure, and 2) the new formulation of motor oil as required by the EPA which I was not aware of at the time. Valvoline still makes the old motor oil in a black bottle, but it certainly wasn’t clear to me on the silver bottle that it was the new formula with less wear additives. I hope this “old dog” has learned a few new tricks from this experience! 🙂

Hopefully we have the oiling problem solved and the old buggy will hang together. Now if this old man can still wheel it down the track so we can have some fun with the ’57 in 2013!

Yup the black bottle is the good stuff, it used to be the black bottle was the good stuff and the silver bottle (VR1) was as good but lasted longer, I don’t know why they followed EPA guide lines on the silver bottle (VR1) as it says VR1 Race Oil,,, The black bottle still says “NOT STREET LEGAL” and is called Valvoline “NSL”

Remember the old Kendall GT1 “Green” oil, we bought some a few years back and when we started pouring it in, and it was not green, we stopped. Apparently Kendall GT1 sold to the company which now markets oil as Bradd Penn. All we used was the Valvoline NSL and Kendall GT1. Is that Bradd Penn still “GREEN” like the old Kendall GT1?

You said you backed down the spring pressure after repairing the lifter bores, what was the installed height before repairing them?

I have had good reviews on Lucas Racing Oils, In Steve’s 383 I built we put the oil in it I like which is Royal Purple 0w10. On his he saw the same thing I have seen thus far, with that 0w10 the oil pressure did not drop off, I assume it just allowed a greater volume of oil. Prior to 0w10 it had 10w30 Valvoline in it

Butch,

Initial valve spring installed height was: 325 @ 1.959 – 850# open

Yes, the Brad-Penn oil is still green.

Everything is looking good with the tunnel ram, I need to pick out a scoop though.

That’s great Butch! Are you starting with the single 4-bbl or the tunnel ram?

I’m not sure, It depends on when the engine is in and what month we are in this spring. If its early on, the tunnel ram, if we are later on getting everything else ready we will start with the single 4bbl and take a week to set up the tunnel ram after a few weekends with the single. Still going for those 660’s, just waiting for him to reply to get them shipped and pay him.

At this point the focus is on the tunnel ram as I need nothing to run the Pro Systems Dominator or Pro Systems 4150. I might have my buddy powder coat the tunnel ram in the next week or so, natural aluminum. He blasts aluminum to restore it, then powder coats it with dull clear coat and it cleans up easy and looks natural aluminum.

I’m ordering some NSL or Bradd Penn next week for initial outing, before switching to synthetic. I’m sticking with my HP4 regardless what I read and hear, I use them on customers engines and mine, and have no failures so I’m sticking with them. I have the new distributor for the tunnel ram too, as I was using a locked out HEI with no mechanical advance and no vacuum advance. All I was using is the pick up however those HEI’s where the mechanical plates press on, come loose under constant use over 7500 RPM as we have went through two GM units. I now have the Crane locked out unit that the roundy track guys are using, as they use their box, coil, wires, and distributor which I am too. I have two adjustable rev limiters from 600 RPM to 9900 RPM with rotary dials, one is all the time rev limiter, and one is like a a two step where its activated by 12 volts

Yeah my Crane 1.625″ springs are 280 @1.950″ and 800 @1.150″. We are at 1.950″.