Years back I transcribed an article by John Dianna from the December 1971 issue of Hot Rod Magazine on popular Modified Production engines of that time period. Remember, this was before aftermarket blocks, cranks, 4-bolt main caps. Here’s that article. – Roger

———————–

Mod Squad

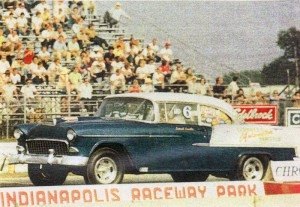

Modified racing is a tough nut to crack. When you do put together a win, it’s usually well earned. There are few people who dominate the cash payout windows in Modified Eliminator, but there is one Texan who persists in giving the troops fits. He is well-known for his “shoebox shaped” ’55 Chevy hardtop, as he has slid the car into a World Champion spot, a Winternationals Champion slot, assorted major runner-up positions and three consecutive NHRA Divisional Points Championships. Of course we are speaking of Carroll Caudle, one of the best guns in the eliminator.

Modified racing is a tough nut to crack. When you do put together a win, it’s usually well earned. There are few people who dominate the cash payout windows in Modified Eliminator, but there is one Texan who persists in giving the troops fits. He is well-known for his “shoebox shaped” ’55 Chevy hardtop, as he has slid the car into a World Champion spot, a Winternationals Champion slot, assorted major runner-up positions and three consecutive NHRA Divisional Points Championships. Of course we are speaking of Carroll Caudle, one of the best guns in the eliminator.

Aside from his driving ability, Carroll has developed another outstanding talent – engine building. He owns and operates a shop in Amarillo, Texas, and from there ships engines all over the country. There are many MP cars running Carroll’s engines, which vary in size from 265 to 400 inches. He has worked with many engine combinations while running his ’55, from a C/MP on down to G/MP. We talked with Carroll and asked him to select the most popular combinations that offer the best power-to-inch ratio for MP or for the ultimate modified street engine.

330-cubic inch small block

This is more a budget engine and can be built using any of the components normally associated with a 327. Actually, this is a “plain vanilla” 327 with a .030-inch overbore.

310-cubic inch small block

This is one of the more popular combinations and is Carroll’s current favorite. He feels this engine offers the best power-to-inch ratio. The block Carroll uses is a 327 with casting No. 3782870. These blocks were usually Powerglide-equipped, so they have had a chance to cure well without excessive main bearing loading. They usually finish well when a fine hone is used. Another important factor is the additional beef in the main web area. Bores are finished .060-inch oversize. In the crank department Carroll is partial to the No. 3735236 “283” steel unit. He has found these cranks need very little work as far as stroke and index are concerned. An interesting note is that a combination of three-inch stroke and .060-inch bore is fine; but when you get to an over-three-inch arm, Carroll suggests boring the block a maximum of only .030-inch, to eliminate excessive cylinder-wall loading. This engine can be built rather inexpensively.

305 and 301 cubic-inch small blocks

These two engines are basically the same as the 310 engine except for bore size differences. The 305 uses a .030-inch-over 327 block, and the 301 uses the standard four-inch 327 bore. Carroll suggests using older pieces rather than the newer 302 engine. At the present time, he feels the four-bolt-main 302 block is just a higher-priced block with less strength. The rod and crank expansion rate changes leave something to be desired and consequently considerably shorten engine life. Even the main caps present a questionable dependability factor over the standard two-bolt caps. Because of the increased journal diameter and overall cap design, it’s .040-to-.050-inch thinner at the top of the cap than is the standard unit. The journal diameter also thins down the area between the main cap bolt hole and the bearing surface. As a result, Carroll doesn’t build any four-bolt-main blocks where extended engine life is of primary importance.

292-inch and 288-cubic inch small blocks

Both of these combinations use the 283 block. Carroll looks for the strongest of the 283 family of blocks, casting No. 3756519. This block features fully threaded mains and a neoprene rear main seal. Like the 310, 305 and 301, these two small engines also use the No. 3735236 283 crank. The 292 is a .060-inch bored block and the 288 is a .030-inch over stock. These engines are extremely popular in the lower MP classes.

As you probably know, there are many possible ways these engines can be built. The overall price of each depends on the cost of the components that make it up. Pistons, rods, crank, etc., are available for many different prices, and in some cases only your pocketbook would know the difference. [End]

Related article:

Memories of Modified: The Rise and Fall of Modified Eliminator

Several things to take into consideration when reading this article.

1) Modified Production and the Gas classes which made up Modified Eliminator were on a cubic-inch-to-weight break. Therefore a 331 was a BIG engine at the time because heads were not available to flow enough to make larger engines competitive.

2) It was not until the advent of aftermarket blocks, cranks & the great heads available today to make a 400 c.i. inch live or produce any real horsepower back then. Even by today’s standards our 331 produces approximately 1.93 hp per cubic inch, our 406 is approximately 1.77 hp per cubic inch. So in the old MP classes the advantage would still be with the smaller displacement motors. Many even ran high-winding 277’s (destroked 283’s) which produced GREAT horsepower with modified Chevy Turbo heads. Of course you had to buzz these motors hard because of the lack of torque.